Brake pad grinding with EHWA BSL and electroplated grinding wheels

The brake pad is a vehicle part which converts kinetic energy into thermal energy due to the force applied to a brake disc or drum, decelerating the vehicle.

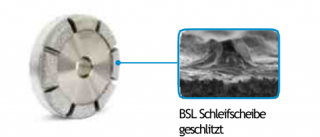

EHWA developed the so-called BSL wheels ("Brazed Single Layer")- and conventional electroplated wheels for the surface processing of brake pads. With the BSL coating, the grits are brazed onto the grinding wheel in a single layer.

With this type, significantly longer tool lifetimes are possible compared to electroplated grinding wheels. In addition to the coating type, specially coated grit types are also good solutions to increase tool life and grinding performance.

BSL - EHWA grinding wheel - brazed diamonds

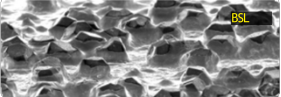

high self-sharpening effect of the grains = high grinding performance

Segmented coating supports chip removal and cooling

Long tool lifetime = reduction of additional costs

Surface structure of BSL grinding wheels

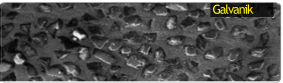

EP - EHWA grinding wheel in galvanic bond

Complex structures or profiles possible

suitable for various materials - composites, ceramics, rubber

very good grinding performance

Relayer possible

Surface structure of the galvanic grinding wheels