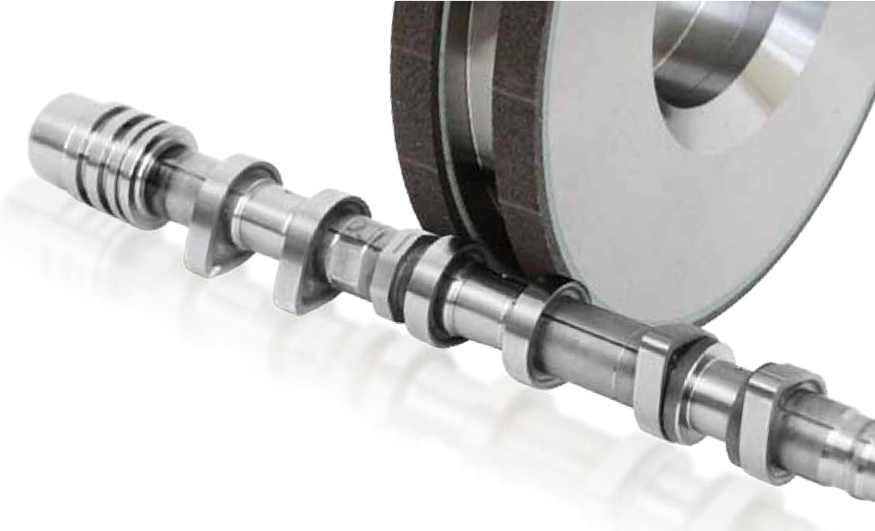

Camshaft grinding with EHWA CBN grinding wheels

Übersicht

Die Nockenwelle steuert über definierte Hubbewegungen das Öffnen und Schließen der Ein- und Auslassventile eines Verbrennungsmotors. Aufgrund der hohen mechanischen Belastungen, Kontaktpressungen und dynamischen Beanspruchungen unterliegen Nockenwellen hohen Anforderungen an Maßhaltigkeit, Formgenauigkeit und Oberflächenqualität. Sie werden überwiegend aus Gusseisen oder geschmiedetem Stahl gefertigt und sind in den Funktionsbereichen oberflächengehärtet.

Diese hohen Oberflächenhärten stellen besondere Anforderungen an wirtschaftliche und prozessstabile Schleifprozesse. EHWA hat hierfür speziell entwickelte CBN-Schleifscheiben mit Keramikbindung konzipiert, die ein effizientes, formstabiles und standzeitoptimiertes Schleifen von Nockenwellen ermöglichen – sowohl im Serien- als auch im Hochleistungsprozess.

Produktprogramm

Produkttypen:

Außenrund- und Profilschleifscheiben für Nocken- und Lagerstellen

Bindung:

VEWN – EHWA Keramikbindung

Körnungen:

B76 – B151

Abmessungen:

Scheibendurchmesser bis Ø 650 mm

Auslegung:

Kundenspezifisch abgestimmt auf Maschinenkonzept, Nockengeometrie und Prozessanforderung

(z. B. Schruppen / Schlichten, Serien- oder Hochleistungsprozess)

Prozess & Vorteile

Längere Abrichtintervalle

→ stabile Profiltreue der Nockenkontur und reduzierte Stillstandszeiten

Konstante Oberflächen- und Formqualität

→ reproduzierbare Nockenprofile und gleichbleibende Rauheitswerte über die gesamte Standzeit

Reduzierte thermische Belastung

→ minimiertes Risiko von Schleifbrand, Rissbildung und Gefügeveränderungen in den Funktionszonen

Hohe Profilstabilität

→ präzise Abbildung komplexer Nockengeometrien auch bei langen Serienläufen

Prozesssicherheit im Serienbetrieb

→ gleichmäßige Zerspanungsleistung bei Guss- und Stahl-Nockenwellen

Fallbeispiel aus der Praxis

VEWN | EHWA vitrified bond

Anwendung: CBN-Profilschleifen von Nockenwellen aus Gusswerkstoff (FCD)

Process parameters:

Increase the lifetime of the grinding wheel by up to 20%

Ergebnis / Nutzen:

-

Verlängerte Abrichtintervalle bei stabiler Profilhaltigkeit

-

Konstante Nockenkontur über die gesamte Standzeit

-

Reduzierter Abrichtaufwand und höhere Maschinenverfügbarkeit

-

Reproduzierbare Oberflächenqualität im Serienbetrieb