The challenge of grinding hard-coated brake discs

The EURO 7 standard, which is expected to come into force in 2026, is the European Union's strictest exhaust and particulate emissions regulation for motor vehicles. Compared to its predecessors, the new standard not only aims to reduce exhaust emissions from the combustion engine, but also includes particulate emissions from brakes and tires for the first time. This is a decisive change in regulation, as modern vehicles - especially electric cars - reduce engine wear through regenerative braking, but still generate particulate matter through the abrasion of brake discs and pads.

With EHWA, you benefit from first-class expertise, the highest precision quality, economical grinding solutions and tools that are individually tailored to your requirements.

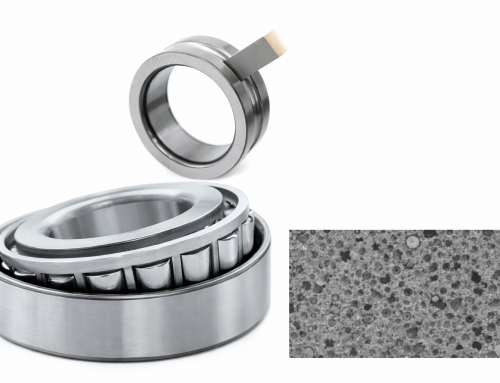

MJ, MS - Bond

EHWA's HMF grinding tools offer customized solutions for the precise machining of brake discs in all-wheel drive vehicles

The HMF grinding tools from EHWA have been specially developed for machining brake discs in all-wheel drive vehicles (4WD). With grit sizes from #170 to #325, MJ and MS bonds and concentrations from 80 to 130, they offer maximum precision and flexibility for cast iron workpieces (FC, FCD).

Customer-specific adaptations such as dimensions and bond types ensure optimum results for different requirements. These tools impress with their efficiency, long service life and excellent surface quality.

EHWA grinding tools offer maximum precision and durability when machining brake discs and guarantee first-class results for demanding applications.

Outstanding performance and durability

| Data | Values |

|---|---|

| Grinding wheel speed (RPM): | 850 |

| Workpiece speed (RPM): | 100~200 |

| Cycle time: | 20m/min |

| Stock removal: | 0.16~0.2mm |

EHWA Mevious Wheel - High-performance grinding wheel for EURO 7

The EHWA Mevious grinding wheel has been specially developed for machining brake discs with an SUS surface after laser cladding. Thanks to the combination of high wear resistance and excellent grinding performance, it offers an optimum solution for demanding grinding processes.

What is laser cladding?

Laser cladding is a process in which a thin layer of metal - in this case stainless steel (SUS) - is applied to the surface of a component using a laser.

Why is laser cladding used?

+ Wear resistance - Increases the durability of the brake component.

+ Corrosion protection - Protects the brake disk from rust and external influences.

+ Material reinforcement - Improves the mechanical properties of the surface.

After this process, however, the surface is not perfectly smooth and must be finished with a special grinding wheel - this is exactly where the

EHWA Mevious grinding wheel used for.

Technical highlights of the EHWA Mevious grinding wheel

+ Hybrid technology - Combination of metal and vitrified bond for optimum grinding performance.

+ Long lifetime - High wear resistance and excellent profile stability.

+ Optimized surface quality - Ensures an even and precise finish.

Grinding process - before/after

STEP1: Workpiece after Laser Cladding - Visible layer structure

STEP2: Grinding with the EHWA Mevious grinding wheel → Smooth and optimized surface

Conclusion

The EHWA Mevious grinding wheel provides manufacturers with a high-performance solution for processing brake components with applied stainless steel coatings. Thanks to its hybrid technology, it ensures a long service life, high grinding performance and perfect surface quality.

Want to know more? Contact us for more technical details!