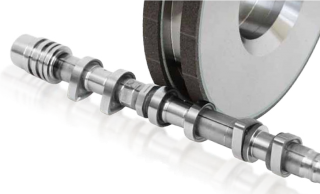

Camshaft grinding with EHWA CBN grinding wheels

The camshaft controls the intake and exhaust valves of a piston engine with the help of mechanical stroke movements. Nowadays, camshafts are made of cast iron and also partly of forged steel. Due to the high mechanical load, these components are surface-hardened.

The high surface hardness is a high challenge to economical grinding processes. EHWA has taken on this issue and developed a special bond for the economical grinding of camshafts. The EHWA specification showed an up to 18% higher stock removal rate with simultaneous high dimensional stability and high surface quality compared to the competition.

VEW | EHWA Ceramic bond

Case study | External cylindrical grinding | Alloy steel :

Workpiece Material: Chromium-molybdenum steel (sintered ring)

Workpiece diameter: 30-50mm – Nocken

Diameter grinding wheel: 450mm

Peripheral speed - grinding wheel: 120m/s

Feed - grinding wheel: 0,08mm/s

Stock removal grinding wheel: 0,8mm/Ø

Specification-EHWA: B126 L200 VEW

Increase of grinding wheel life time up to 20%.

Advantages of EHWA CBN grinding wheels:

High stock removal rate with low spindle load

high surface quality

High dimensional stability

High dressing cycle