Bearing grinding with EHWA CBN grinding tools

Übersicht

Das Lagerschleifen stellt höchste Anforderungen an Maßhaltigkeit, Oberflächenqualität und Prozesssicherheit. Beim Schleifen von Innen- und Außenringen sowie Laufbahnen aus hochgehärteten Wälzlagerstählen (z. B. 100Cr6) kommen überwiegend CBN-Schleifwerkzeuge zum Einsatz, da sie eine stabile Bearbeitung bei hohen Schnittgeschwindigkeiten ermöglichen.

Produktprogramm

CBN-Schleifwerkzeuge für das Außen-, Innen- und Laufbahnschleifen von Lagerringen in der Serien- und Großserienfertigung.

-

Produkttypen: Außenrund- und Profilschleifscheiben

-

Bindung: VEWN – keramische Bindung für stabiles Abrichtverhalten und lange Standzeiten

-

Körnungen: B76 – B151, abgestimmt auf Abtragsleistung und Oberflächenanforderung

-

Abmessungen: Ø bis 650 mm

-

Auslegung: kundenspezifisch nach Maschine, Werkstück und Prozess

Ausgelegt für prozesssichere Schleifprozesse mit hoher Maß- und Formgenauigkeit bei wirtschaftlichen Taktzeiten.

Prozess & Vorteile

Längere Abrichtintervalle

→ höhere effektive Standzeit, reduzierte Nebenzeiten und stabile Taktzeiten

Konstante Oberflächengüte

→ reproduzierbare Rauheits- und Formwerte über die gesamte Werkzeugstandzeit

Reduzierte thermische Belastung

→ geringeres Risiko von Schleifbrand, Anlassen und Gefügeveränderungen

Form- und Maßstabilität

→ sichere Einhaltung enger Rundheits-, Welligkeits- und Maßtoleranzen

Hohe Prozesssicherheit

→ stabile Serienprozesse bei wechselnden Losgrößen und langen Laufzeiten

Fallbeispiel aus der Praxis

VBME | Schleifscheiben in Keramikbindung

Fallbeispiel: Bohrungsschleifen

Process parameters:

Increase the lifetime of the grinding wheel by up to 20%

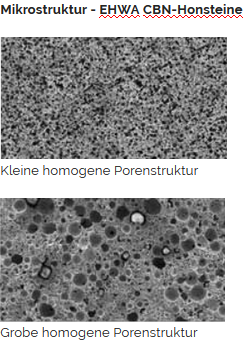

VHWPN | EHWA honing stones in ceramic bond

Case study - Raceway honing: