Flute/thread grinding with EHWA grinding wheels

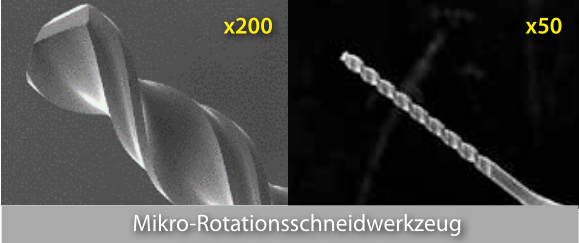

In drill and milling cutter production, flute grinding is the key technology and the main cost factor.

EHWA has been developing special synthetic resin and vitrified bonds for years, which allow enormous feed rates and thus create a clear competitive advantage over other competitors.

The open-pored bond structures in particular stand out due to their grinding performance.

VC | EHWA vitrified bond

Case study | flute grinding | carbide:

Advantages | EHWA - Precision tools

BG | EHWA synthetic resin bond

Case study | Circular saws / hobs / cutting tools | HSS and carbide: