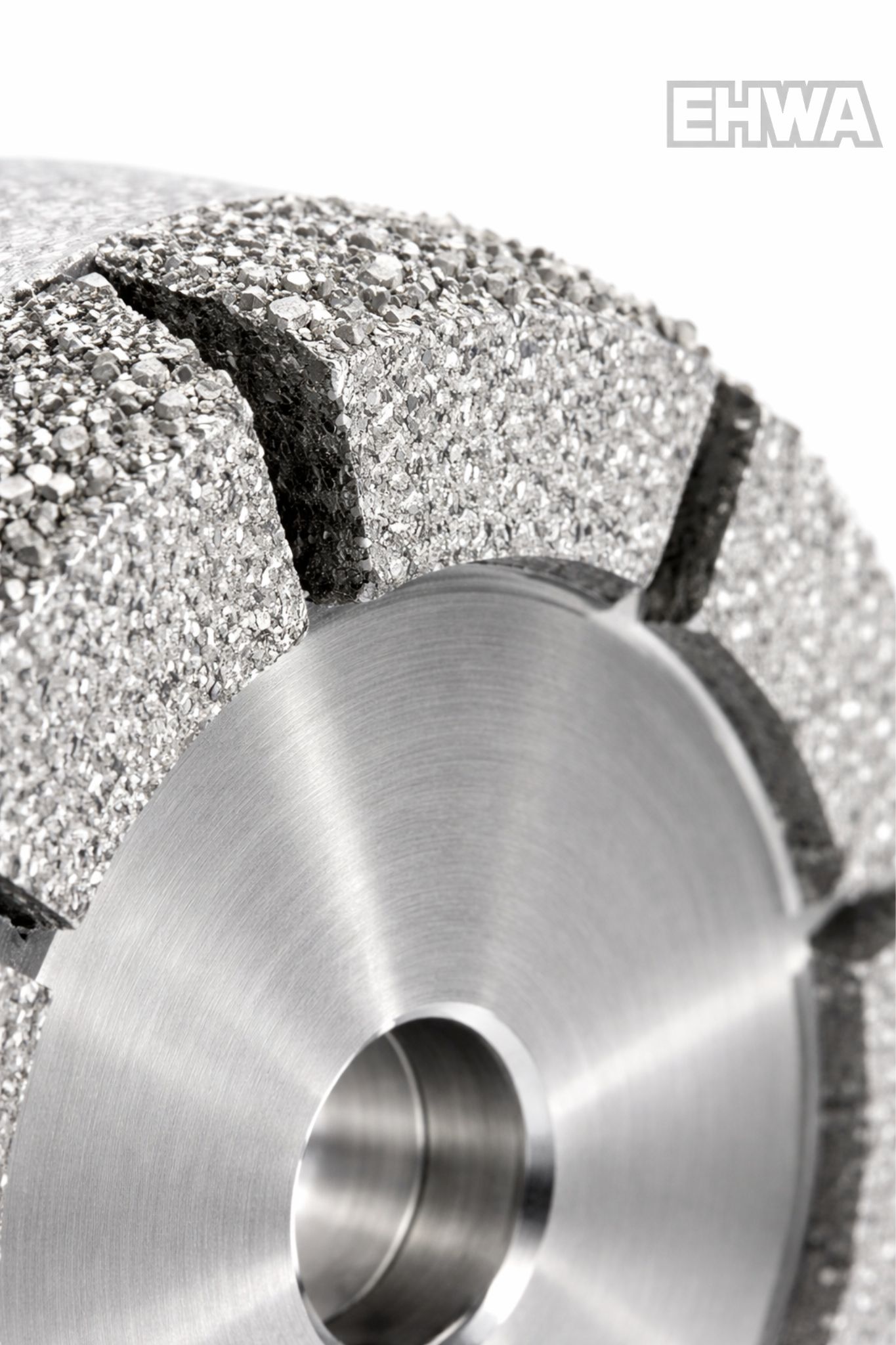

Brake pad grinding with EHWA BSL and electroplating wheels

Übersicht

Beim Schleifen von Bremsbelägen stehen Maßhaltigkeit, Oberflächenqualität und Prozessstabilität im Fokus. Unterschiedliche Reibbelagmischungen – von organischen bis hin zu metallhaltigen Compounds – erfordern ein Werkzeug mit stabiler Schneidfähigkeit und kontrollierter Spanbildung.

Zum Einsatz kommen geschlitzte BSL- oder galvanisch gebundene Schleifscheiben für Serien- und Großserienprozesse. Sie ermöglichen das wirtschaftliche Schleifen von Reibflächen, Fasen, Nuten und Kanten bei gleichzeitig hoher Reproduzierbarkeit.

BSL-Schleifscheiben bieten durch ihre offenporige Struktur einen ausgeprägten Selbstschärfeffekt und konstante Zerspanungsbedingungen. Galvanisch gebundene Werkzeuge gewährleisten eine hohe Profilgenauigkeit und sind besonders für komplexe Geometrien geeignet.

Ziel ist ein thermisch stabiler Schleifprozess mit definiertem Materialabtrag und gleichbleibender Qualität über hohe Stückzahlen.

Produktprogramm

BSL Schleifscheiben (Brazed Single Layer)

-

Bindungssystem: Metallurgisch gelötete Einschichtbelegung (Vakuum-Hartlötprozess)

-

Schleifmittel: Diamant (organische/keramische Beläge) oder CBN (hochmetallhaltige Mischungen)

-

Kornüberstand: ca. 60–80 % der Korngröße → große Spanräume

-

Körnungen: typ. D54 – D181

-

Ausführungen: Geschlitzt, segmentiert oder zylindrisch (z. B. für Trommelbremsbeläge)

-

Abmessungen: Kundenspezifisch gemäß Maschinen- und Spannkonzept

Einsatzschwerpunkt: Hochleistungs-Planschleifen und Dickenkalibrierung mit maximaler Abtragsleistung, thermisch stabilem Prozess und hoher Standzeit in Großserie.

Galvanik Schleifscheiben (Nickel-gebunden, EP)

-

Bindungssystem: Elektrochemisch abgeschiedene Nickelschicht (einschichtig)

-

Schleifmittel: Diamant oder CBN, an Werkstoff angepasst

-

Kornüberstand: ca. 30–50 % der Korngröße

-

Körnungen: typ. D64 – D181

-

Ausführungen: Profiliert für Fasen-, Nut- und Konturbearbeitung; geschlitzt für verbesserte Spanabfuhr

-

Besonderheit: Wiederbelegung des Grundkörpers möglich

Einsatzschwerpunkt: Geometrisch definierte Fasen- und Nutbearbeitung mit hoher Profilgenauigkeit und reproduzierbarer Kantenqualität.

Prozess & Vorteile

Hoher Kornüberstand (BSL)

→ kühler Schliff und stabile Oberfläche

Hohe Profilgenauigkeit (Galvanik)

→ reproduzierbare Fasen- und Nutgeometrie

Stabile Kornverankerung

→ weniger Stillstand und konstante Qualität

Fallbeispiel aus der Praxis

EP | EHWA BSL-Bindung

Application: Schleifen von Bremsbelägen (NAO / Low-Steel) in der Serienfertigung

Ziel: Erhöhung der Standzeit bei gleichzeitig konstanter Fasen- und Oberflächenqualität

– Werkstoff: Organisch gebundene Reibbelagmischung mit metallischen Anteilen

– Prozess: Planschleifen und Fasenbearbeitung

– Fokus: Prozessstabilität / Reduzierung thermischer Belastung

Process parameters:

Standzeiterhöhung der Schleifscheibe: bis zu 25 %

Weniger Werkzeugwechsel → höhere Anlagenverfügbarkeit

Konstanter Materialabtrag → reproduzierbare Belagdicke

Reduzierte Wärmeentwicklung → geringeres Risiko von Oberflächenschädigung

Senkung der Stückkosten durch stabile Taktzeit und geringeren Ausschuss